v3Di V3D Interaction

The Technology Leader in Volumetric 3D Display

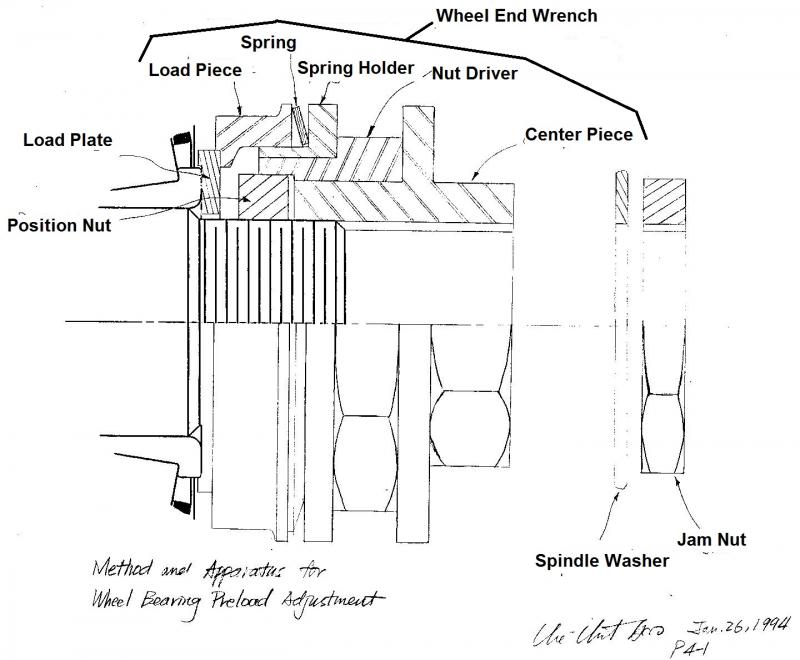

Wheel End Wrench

Field: Design

Topic: Wheel End Wrench for truck wheel bearing preload adjustment

(Under The Timken Company design competition award)

Summary

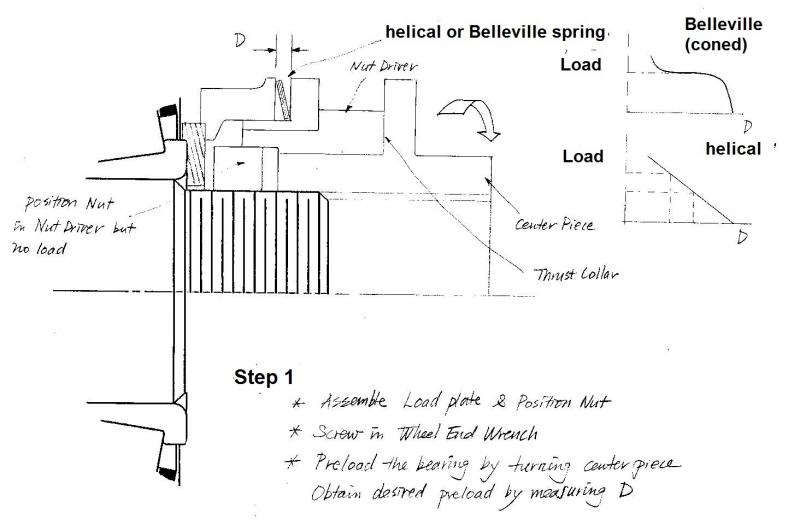

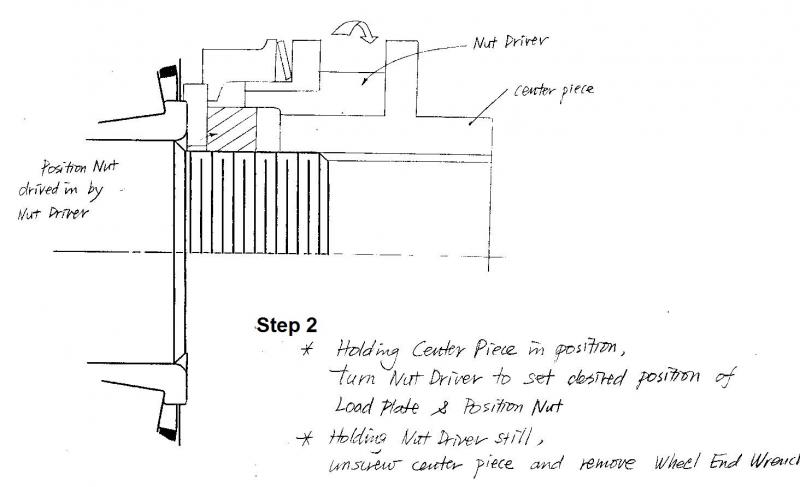

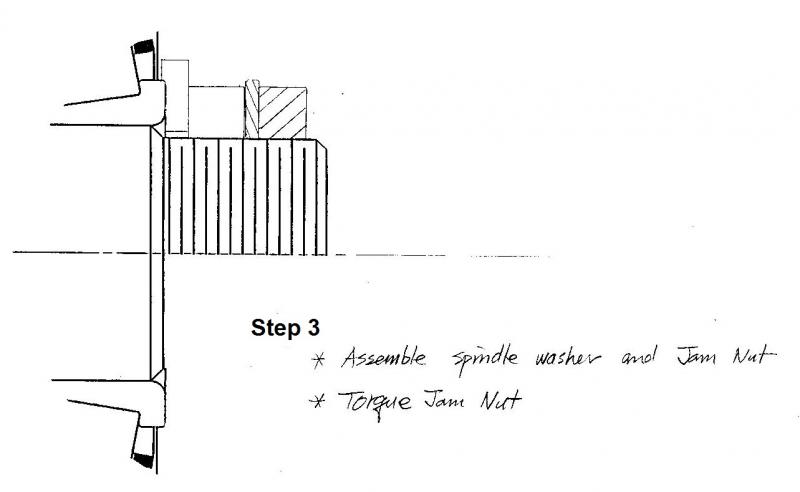

The Timken Company came to MIT seeking design idea to improve their existing wheel bearing preload adjustment procedure. The “Wheel End Wrench” design by Che-Chih Tsao is a simple hand tool capable of setting preload directly in a 3-step operation. The wrench has 5 elements. The main feature is that the Center Piece drives the wrench to set preload, while the Nut Driver can rotate independently w.r.t. the Center Piece. A (set of) Belleville spring is used and preload is set directly by driving the Center Piece to load the spring to a predetermined deformation amount. The Nut Driver then drives the Position Nut to secure the loading distance. By holding the Nut Driver still, the Center Piece can then be unscrewed from the wheel end thread and the whole wrench can be removed. In the final step, Spindle Washer and Jan Nut are assembled to lock Position Nut.

Major innovations/contributions:

-- Set preload directly using a (set of) spring in the wrench as a direct measure of axial load force.

-- Advantage in simple design and easy operation in the field.

Copyright 2012 v3di.com. All rights reserved.